DTG VS screen Printing: Which One Is Better For Small Business?

Dtg printer and screen printing machine, which one should i choose for my business?

- | Tips: This article will take you about 6 minutes

There are many ways to print custom clothing, but the two most popular are DTG digital direct printing and screen printing. Choosing the right business model for your online e-commerce business is the first key to satisfying customers, saving costs, and being able to expand as your business grows.

Because there's so much at stake, it's important to research your options by asking questions about both printing methods, such as: Is it right for my product? How is the price/performance ratio? Is it environmentally friendly?

As a practitioner who has been engaged in the T-shirt printer market for 25 years, from a technician in the early years to a salesman and company manager in the later years, let me share my views! We'll look at the differences between DTG and screen printing, the designs they're best suited for, and the sustainability of each technology.

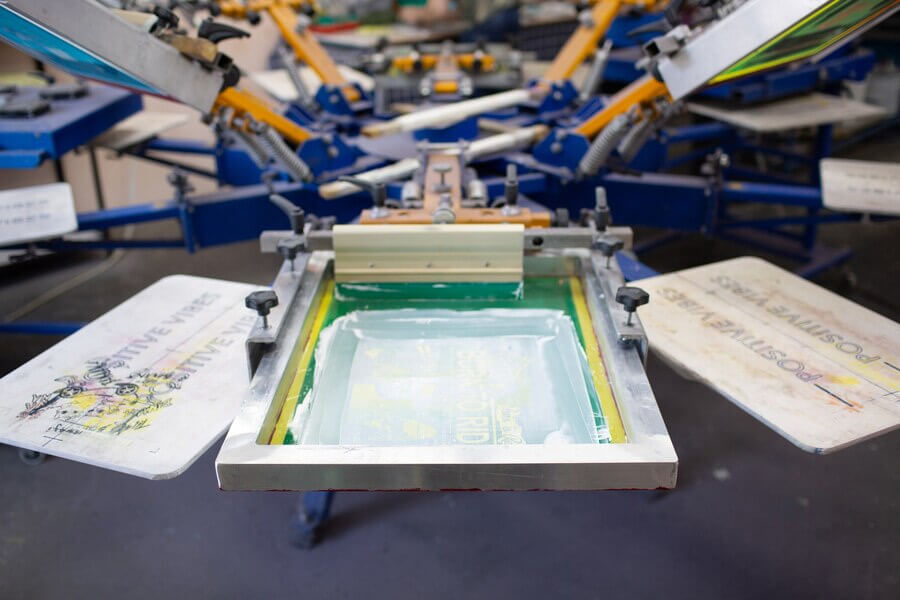

What is screen printing?

Screen printing is a printing method in which ink is pushed onto fabric through a woven mesh (also called a mesh stencil). The ink does not soak into the fabric but sits on top of the product.

How does screen printing work?

With screen printing, a special screen must be made for each element of the design. Once complete, the colors and elements of the design are applied to the garment layer by layer. The more layers your design has, the longer it will take to print and the thicker the design will be on the product.

The long setup time is why screen printing is primarily used for batch printing projects. If creating a template for your design takes hours, it's not cost-effective to print just one or two T-shirts.

What type of design is best for screen printing?

Screen printing works best with solid graphics without small details. Think basic typography, geometric designs, symbols and shapes. This is because creating templates for complex designs is very time-consuming, and it can be difficult to get the details right during the printing process.

Since each color is applied individually, screen printing is also mostly used for designs with few colors. Print providers often limit the number of colors that can be included in a design, usually not allowing more than 9.

Is screen printing environmentally friendly? Is it expensive?

As a business owner, you should also understand how your business impacts the environment. Sellers who use screen printing often order in bulk and then ship items as orders come in. This is why there is a possibility of overproduction, which is one of the main issues that the sustainable fashion movement is addressing.

If the products you screen print are not sold, they may end up in landfill or incineration, causing contamination. What's more, screen printing uses a lot of water and is usually done using plastisol screen printing ink, which does not biodegrade.

Screen printing cost depends on the quantity of items you order. For example, if you order in bulk, screen printing is usually the cheapest option. This is because screen printing templates are made manually and require time to prepare.

Is the screen printing quality good? Is it durable?

Screen printing technology is known for its quality. The colors are bright and rich and the printing is very durable. For best results, screen print a simple design without a lot of detail or color.

Screen printed shirts are durable if you take care of them properly. To avoid ink cracking, peeling, and fading, do not wash screen printed garments in hot water, avoid bleaching, and always turn them inside out before washing.

Is screen printing the right choice for your business?

The final price for screen printing bulk orders depends on the number of colors in your design and the screens required for printing. So if you're just starting out or want to try out design, it can be financially challenging.

Bulk ordering also means, storage of printed garments. This limits the number of designs you can offer in your store, as each design must be printed in batches. Also consider whether you will be able to sell all your prints so you don't create textile waste. For entrepreneurs who haven't yet established a customer base, this can be difficult to predict.

Some printing services will require you to submit a print file separated into layers for each color. They may ask you for the color code of the ink you should use when printing your design. So if you're looking for an "upload your design and forget the rest" type of experience, screen printing isn't the right choice for you.

Now let us discuss the second printing method - DTG printing. How does it work and is it the right choice for your business? Read on to find out.

What is DTG printing?

DTG printing, literally translated as digital direct printing, is a printing method that sprays ink onto clothing. The ink then soaks into the fibers of the garment. It's like printing on paper.

How does DTG printing work?

For DTG printing, a digital printer is used to spray water-based ink onto the fabric. A pre-treatment solution is applied first to help the ink bond to the fabric. Next, the garment is mounted on the platen and placed into the printer, where it can be printed in just a few minutes. Finally, the ink is cured to make the print more durable.

DTG printing works best with 100% cotton, but cotton blends will work too. The main advantage is that printing one-time documents is easy as there is almost no setup time.

If you have a DTG printer, such as ANTPRINT A2plus DTG Printer, when your customer orders a T-shirt in your store, you only need to automatically receive the order, print your design on the T-shirt, and print it directly Send to your customers.

You can use this DTG printer to build an official independent website + DIY design system, allowing customers to upload pictures for DIY design, saving customer service time, avoiding the time-consuming work of uploading pictures back and forth for modification, and increasing order volume. Of course, you can also pass

DTG printer creates an independent website, allowing customers to design T-shirts, coffee cups, hats, mobile phone cases, canvas bags and other products on your independent website; you can also design the main product renderings and then put them on Amazon. Sold on eBay, Shopee, Walmart and other platforms.

What type of design is best for DTG?

DTG printers offer many color options, which means you can print detailed designs and realistic images with virtually no color restrictions. This is important for businesses who want to experiment with a variety of colors and designs.

What you want to avoid using DTG is transparency. Elements with less than 100% opacity don't translate well in DTG printing, and the printer will try to make up for the missing color by spreading the ink, resulting in lots of gaps in the fabric.

Apart from this, you can use detailed designs and color patterns as per your requirement. For best results, DIYSKU recommends creating graphics in a color profile that best matches the DTG printer's color possibilities.

Is DTG printing environmentally friendly?

DTG is a more sustainable fashion business model than screen printing. Mainly because one-time printing allows companies to avoid overproduction and textile waste. With 92 million tonnes of textiles wasted in the fashion industry every year, business models like this are a game changer.

How long does DTG printing last?

If you follow the care instructions, DTG prints will stay sharp and vibrant for a long time. To prevent them from fading or cracking, machine wash garments on gentle cycle, avoid bleach and fabric softener, and do not iron printing.

Is DTG printing the right choice for your business?

Most third-party printers have no minimum order quantity for DTG products, so you don't have to worry about inventory issues. This method of printing also enables businesses to use printing services on demand.

Using DTG, the entire design can be printed in one go. Since DTG has no color count, there is no additional setup time to start printing, so your order is fulfilled once the print file comes through. This printing model gives you the freedom to introduce new designs or enter new markets without losing any money. If the product doesn't sell, you can discontinue it or replace it.

DTG and screen printing: Which one is right for you?

DTG and screen printing produce high-quality prints, but they differ in method and cost.

DTG uses a printer to spray ink onto the garment, while screen printing layers the ink on top of the fabric. Best of all, DTG enables on-demand fulfillment with no upfront costs, while screen-printed products are ordered in bulk.

Choose your printing method wisely

Whether you want to create and expand your apparel business using DTG printer or screen printing machine is entirely up to you. Before making your final decision, please consider:

-

Your brand image

-

Design complexity

-

Your product quantity requirements

If you're looking for an easy way to successfully grow your business, print on demand is your best option. Using this printing method, it's easy to introduce new designs into your store risk-free, and you don't have to worry about keeping inventory or shipping items yourself.

Leave a comment